Saddlery, faults, safety and maintenance

By Sam Belasco, Master Saddler at the Household Cavalry

Saddle fitters who read the feature and submit correct answers to the quiz will be awarded 30 minutes CPD training time from the Society of Master Saddlers (SMS).

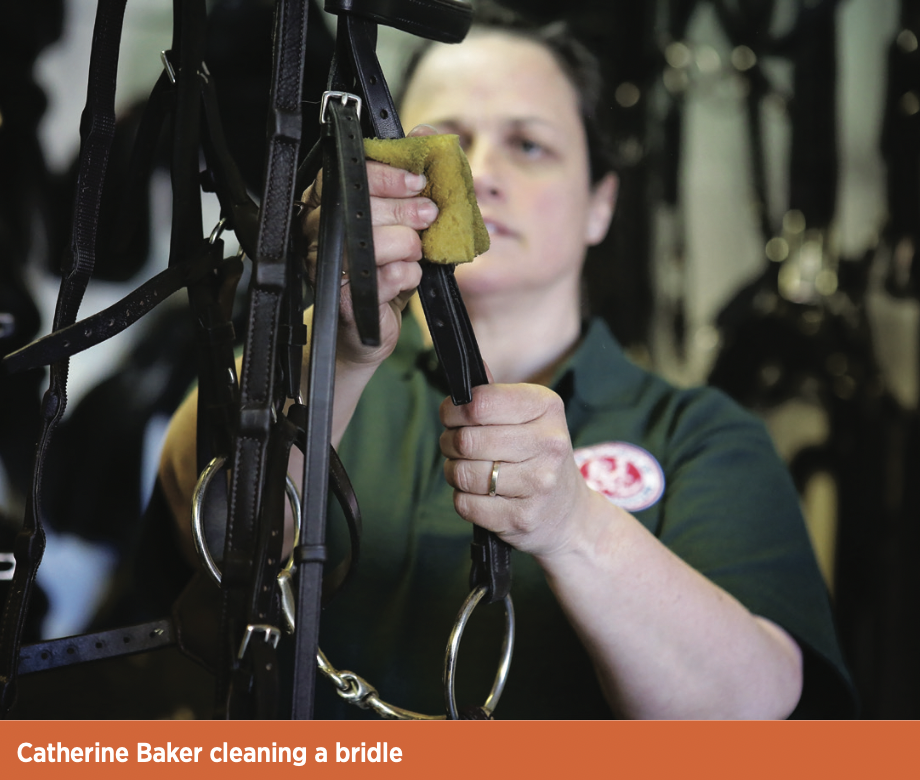

Cleaning tack – not the most glamorous, but one of the more important equestrian subjects.

An all-too-familiar process is a quick wipe with a cloth for the leather and a dunk in a bucket for the bit. Then, it’s back on the peg, ready for the next ride.

How often - honestly - do we completely strip down our tack to check and clean it thoroughly before reassembling it? There’s always an excuse or something better to do.

However, when we think how much we rely on our tack, and how much trust we put in it - not only for our safety, but the welfare and the comfort of our horses, then maybe it’s something we should all pay a little more attention to.

When new recruits join the Household Cavalry Mounted Regiment riding school, it’s drummed into them from day one to strip every removable piece of horse kit, inspect it and clean it every time it’s used.

Why? Well, it’s the same reason we strip a weapon to clean it. When your life could potentially rely on a piece of equipment, you want to know that every working part is safe, clean and able to function as needed.

Tack safety and fault finding doesn’t have to be a lengthy process requiring months of training. Simple routine checks carried out thoroughly is often all that’s required to ensure it’s fit for purpose, safe and that equine welfare is ensured.

WHAT TO LOOK FOR

The majority of horse equipment is made from leather. This is a natural product and, like our skin, no one piece is identical to another. It may have had exactly the same tanning process, but the properties can differ from one hide to another, therefore so can the wear.

First check the overall condition of the leather, look for dryness and cracking, especially where the leather turns around buckles. Wherever there is stitching, check for loosening, wear or breakage of threads. Salt from sweat can, over time, erode stitching if it’s not removed regularly.

Check buckles and metal fittings, paying close attention to the overall condition; is there any rust or cracking? Is the tongue of the buckle supported correctly or can it pull through? Check the back of tongues, in particular on stirrup leathers where they rest against the stirrup bars. This is a very common, often overlooked safety issue.

If bridles are never stripped down, the buckles constantly rest on the same part of the leather. Over time, properties within the metal can cause leather discolouration or damage.

Making sure the holes are all in good order and not torn is another must, particularly on saddle girth straps. The practice of leaving the girth attached one side and swinging it over the saddle when not in use is another ‘no-no’. It can cause unnecessary strain on the girth straps - if caught doing this, Army recruits are counting out the press-ups.

If billet hooks are used on rein ends and cheek-pieces rather than buckles, make sure they are firmly in place and not tearing through – it only takes a moment to do but could prevent a disaster.

Since we use them to communicate with our horses, we have a responsibility to make sure bits are properly cared for. It’s important to understand the material they are made from, and regularly check them for cleanliness, wear and sharp edges, so as not to cause the horse discomfort.

BASIC MAINTENANCE

Many manufacturers have a particular cleaning product they recommend and often supply it with an item.

Some new leather products have a high grease content and may not need to be treated before use. If, however, the leather is particularly stiff, you can apply a thin coat of a good quality leather dressing or balm to the underside and allow it to soak in.

Always use balms or saddle soaps made from natural ingredients such as lanolin, tallow and beeswax. Avoid the liquid soaps as they often contain alcohol or other chemicals to keep them liquid.

Saddle soaps with a high glycerine content may cause darker leather to lose its colour and can cause some leathers to become hard or dry. Check labels for ingredients, or if there is no list, smell the product to get an indication of the presence of any strong chemicals.

Before applying dressing or balm, remove all excess dirt and sweat with a sponge or cloth and warm water. Never soak or submerge leather in water though.

If applying dressing, put some into an old saucer or similar, and apply it to the underside of the leather with a clean dry paint brush, or small sponge - allow it to soak in, and if it still appears to be particularly dry you could apply a second coat.

Once this has completely soaked in, finish by applying good quality leather balm or saddle soap sparingly on all surfaces, using a sponge or cloth which is dry, or almost dry. If any dressing or soap becomes lodged in the stitching or adjustment holes, use a soft brush or cotton bud to remove it.

If tack becomes completely soaked while riding, it should be dismantled as soon as possible and any surface dirt removed. It should then be left to dry completely naturally somewhere cool.

Never, ever be tempted to place saddlery near any artificial heat to speed up the drying process as this will cause it to become hard and brittle, and possibly beyond saving. Once dry, if it has become stiff or hard, apply a coat of leather dressing followed by saddle soap or balm.

Patent leather can be wiped clean with a little washing-up liquid in water, followed by buffing with a dry cloth.

Do not use any dressings or balms on patent, or any dressings on softer leather areas such as the panel or knee pads on saddles, the padding on bridles or any suede areas. These are all tanned differently, and the oils can damage them.

Suede should be kept dry, if possible. If it does get wet, it should be allowed to dry naturally in a cool dry place. Any dirt can be removed with a purpose-made suede brush.

Main tack image by Dorian Krauss